Process Development

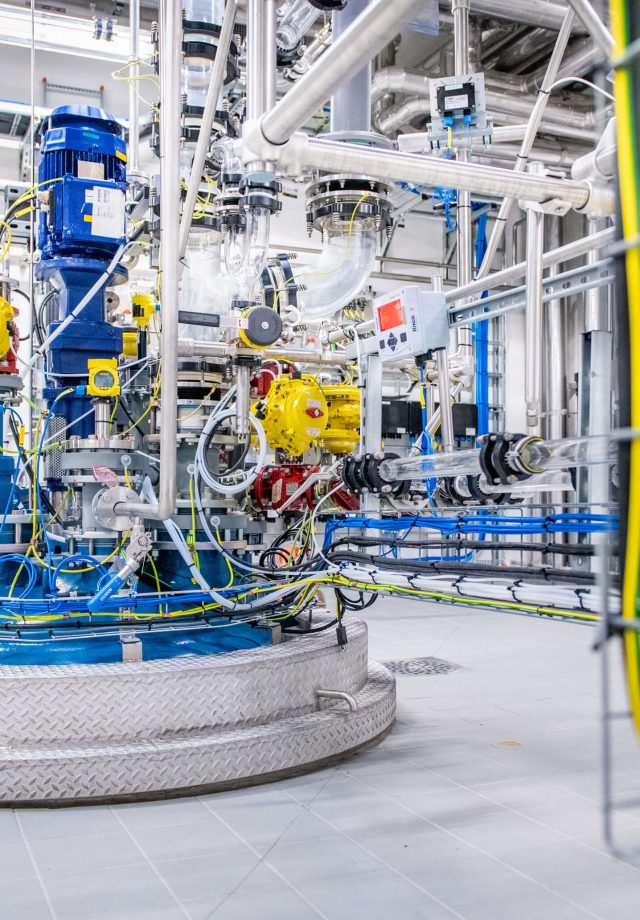

Continuous investment in technologies and best-practices allows us to offer safe and high quality process development, safety assessment, and analytical development labs.

Robust Process Design As an industry leader, when developing or scaling projects, we utilize the latest analytical and statistical techniques to ensure the maximum speed without undue risk.

- Key process analytical techniques

- FBRM Focused Beam Reflectance Measurement (Lasentec)

- nIR gas, liquid and solid probes (Bruker)

- Mid IR gas (Hamilton)

- RAMAN liquid and solid (Kaiser)

- Gas mass detector (Hiden)

- Crystallisation Video Imaging (Sony/Polytec)

- Turbidity (InPro)

- Multiple Buchi Autoclaves for hydrogenation and pressure reactions

- Crystallization investigations

- Hot stage Microscope

- Stereo Microscope

- Crystal 16

- Lab filter dryer

- Filtration speed measurement

- Evaporative Light Scattering Detectors

- Corrosion testing

- Parallel synthesis units (for preparation of validation: determination of normal operation and proven acceptable ranges NOR/PAR)

- Preparative HPLC (for impurity isolation and development of preparative separation processes)

Safety Assessment Our dedicated team evaluates the safety of each process prior to scale up to the pilot plant. Heat of reaction, build-up of energetic intermediates, gas-formation and thermal stability of reaction mixtures, evaporation residues, and wet and dry cakes are thoroughly evaluated. Safety is guaranteed by using extensively different types of process analytical technologies (PAT) in the liquid and gas phases.

Standard in-house testing:

- Micro-reaction Calorimetry

- DSC (available at several departments)

- RC-1 Calorimetry Accelerated Rate Calorimetry

- Carius tube testing

- BAM Fallhammer (Shock sensitivity)

- Other tests may be performed externally after agreement of the customer.